Rotary Shear cross cutting machine vs Guillotine Shear cross cutting machine : Application Areas of Feeding Methods and Automatic Stacking, Along with Selection Strategies

Abstract: In modern coil processing industries such as printing, packaging, labeling, adhesives, composite materials, and new energy battery electrode manufacturing, cross-cutting machines are core equipment that determine the dimensional accuracy, cut quality, and production efficiency of final products. Among them, rotary shear (circular knife cutting) and guillotine shear are the two mainstream cutting technologies. This article aims to provide an in-depth analysis of the technical principles and performance characteristics of rotary shear and guillotine shear machines, with a focus on their feeding methods and automated material handling solutions such as automatic stacking systems. Ultimately, it offers a scientific and rigorous decision-making framework for users across different industries.

1.Core Technology Comparison Between Rotary Shear and Guillotine Shear Machines

To make the correct selection, it is essential to first understand the intrinsic mechanisms and applicable boundaries of the two cutting methods.

1.1 Rotary Shear Machine :

Technical Principle: Uses a pair of opposing rotating circular blades (upper and lower knives) to perform cutting during continuous material movement through the "shearing" action at the contact point. The process resembles scissors but with continuously rotating blades.

Key Features:

High-speed continuous operation: Synchronizes with material line speed, making it ideal for high-speed, high-volume production, with speeds reaching hundreds of meters per minute.

Cut quality: Smooth, burr-free cuts, especially suitable for soft materials like films and paper.

Dynamic cutting: Enables fixed-length cutting without stopping the material, ensuring high productivity.

Limitations: Limited capability for extremely hard, thick, or brittle materials (e.g., thick metal plates, rigid plastic sheets); minimum gap requirements between blades restrict the smallest cutting width.

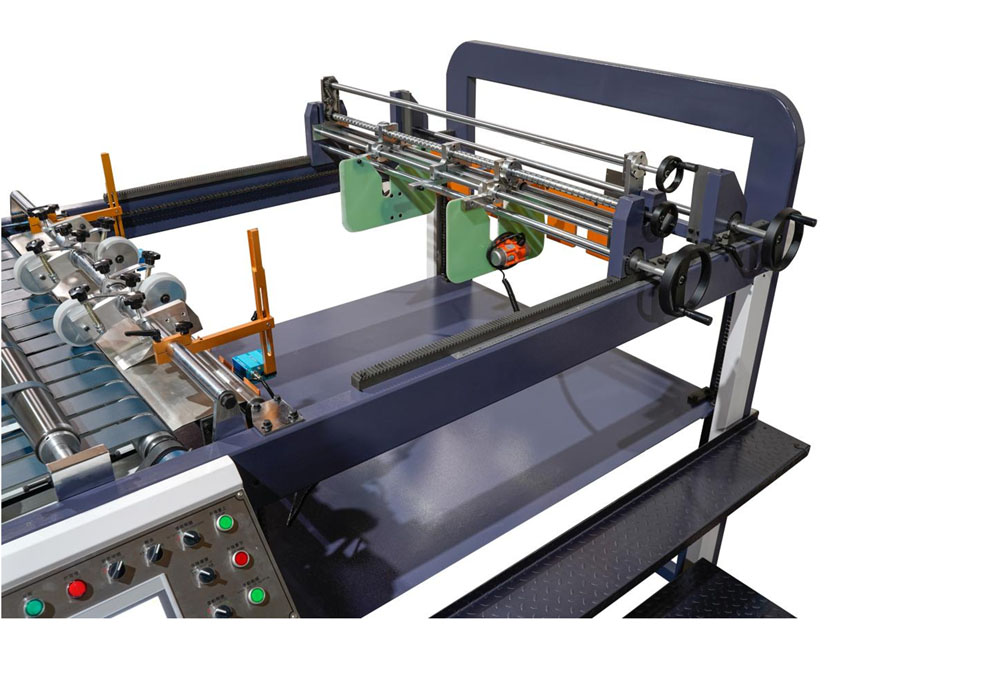

1.2 Guillotine Shear Machine

Technical Principle: Uses a sharp blade (moving knife) to cut vertically (or laterally) in a guillotine-like motion perpendicular to the material surface. The material typically requires a brief pause or significant slowdown during cutting.

Key Features:

High precision and right-angle cuts: Vertical blade motion ensures extreme length accuracy and perfect right-angle cuts, ideal for products with strict dimensional requirements like cartons and cardboard.

Wide material adaptability: With blades of varying strength and edge types, it can cut materials ranging from soft films to thicker cardboard, corrugated board, insulating materials, and even thin metal sheets.

Limitations: Intermittent motion limits production speed compared to rotary shear; higher mechanical impact demands greater machine rigidity.

Comparison Summary Table:

Feature |

Rotary Shear Machine |

Guillotine Shear Machine |

Cutting Principle |

Rotating, continuous shear |

Vertical, intermittent punch-cut |

Production Speed |

High, suitable for continuous production |

Medium, limited by start-stop cycles |

Cutting Accuracy |

High |

Extremely high |

Cut Quality |

Smooth, ideal for soft/thin materials |

Clean, suitable for diverse materials |

Applicable Materials |

Films, paper, thin composites |

Cardboard, corrugated board, insulation, thin metal sheets |

Equipment Cost |

Typically higher (due to precision dynamic control) |

Lower, but high-rigidity models can be costly |

2.Feeding Methods: The Starting Point of Automation and Efficiency

The stability and automation level of the feeding system directly determine overall production efficiency and human-machine collaboration. Main methods include:

2.1 Manual Feeding

Description: Operators use cranes or forklifts to place coils on the unwinding stand, manually aligning and threading the material.

Applicable Scenarios: Small-batch, multi-variety, low-frequency production or situations with limited initial budgets.

Pros/Cons: Lowest equipment cost but high labor intensity, low efficiency, safety risks, and reliance on operator experience, which may lead to material damage due to human error.

2.2 Semi-Automatic Feeding

Description: Equipped with hydraulic or electric lifting unwinding stands, operators can easily center the coil via control buttons. Often integrated with pneumatic or electric alignment aids for threading.

Applicable Scenarios: Medium-batch production, mainstream for small and medium-sized enterprises.

Pros/Cons: Significantly reduces labor intensity, improves feeding efficiency and safety, with moderate investment costs.

2.3 Fully Automatic Feeding System

Description: Comprises raw material storage racks, automated guided vehicles/robots, feeding carts, alignment devices, and correction systems. Enables unmanned coil transfer, positioning, loading, and initial alignment from warehouse to machine.

Applicable Scenarios: Large-scale continuous production, e.g., big flexible packaging plants, new energy battery electrode workshops, or modern enterprises aiming for "lights-out" factories.

Pros/Cons: Maximizes efficiency for 24/7 production, reduces labor dependency, and ensures process consistency. However, initial investment is substantial, systems are complex, and facility layout/infrastructure requirements are high.

Selection Advice: Feeding methods should be chosen based on daily/monthly material consumption, coil change frequency, labor cost budgets, and future automation upgrade plans. For long-term competitiveness, selecting equipment with upgradeable interfaces for full automation is wise.

3. Unloading and Automatic Stacking: The Critical Final Stage

Unloading ensures final product quality and facilitates subsequent storage/transport. Automatic stacking technology is key to efficiency here.

3.1 Conventional Unloading

Belt Conveyor Unloading: Cut sheets are transported via conveyor belts for manual stacking.

Applicable Scenarios: Highly variable product sizes or low-output situations. Flexible but labor-dependent, prone to scratches or misalignment.

3.2 Automatic Stacking Systems

Technical Principle: Uses vacuum suction cups, belts, or pushers to automatically stack cut sheets in preset quantities and patterns (e.g., interleaved for stability) on pallets or carts.

Main Types:

Lift-table Stackers: The platform descends as stack height increases, maintaining constant pickup height. Ideal for large/heavy products.

Robotic Stacking Systems: Employ industrial robots for flexible handling of diverse sizes and complex patterns, capable of interfacing with multiple production lines.

Advantages:

High efficiency, synchronized with the cutter.

Ensures quality by avoiding human contact-induced contamination, creases, or scratches.

Neat stacks simplify bundling, packaging, and transport, enhancing product presentation.

Reduces labor for fully automated unloading.

Selection Advice: Consider product size, weight, surface properties (suction cup compatibility), hourly output, and downstream packaging needs. For fragile or thin materials, prioritize non-contact or adjustable suction systems.

4.Comprehensive Selection Strategy: Building a Production-Matched Solution

Selecting a cross-cutting system is not an isolated decision but a systematic engineering process. Follow these steps:

4.1 Define Core Material and Process Requirements:

Material type and thickness: Films/paper vs. cardboard/composites? This directly dictates rotary or guillotine shear.

Dimensional accuracy and cut quality needs: Guillotine for precision (e.g., premium packaging), rotary for speed and smoothness (e.g., labels).

Maximum production speed (m/min or sheets/hour): High-speed lines favor rotary shear + full automation.

4.2 Assess Production Scale and Automation Goals:

Batch size and changeover frequency: High-volume, low-changeover suits full automation; high-mix, low-volume requires flexibility.

Labor costs and "unmanned" vision: Long-term automation mitigates rising labor costs and ensures consistent quality.

4.3 Evaluate ROI and Future Scalability:

Budget planning: Include installation,test, training, and maintenance costs beyond initial purchase.

Modularity and expandability: Choose platforms upgradable with automated feeding/stacking modules to protect initial investment.

4.4 Supplier Expertise and After-Sales Service:

Select vendors with deep industry experience, offering end-to-end services from process analysis to commissioning.

Ensure timely technical support and spare parts availability to maintain uninterrupted production.

Conclusion

Rotary and guillotine shears are complementary, not interchangeable, technologies, each dominant in its respective applications. The automation level of feeding and unloading systems has become a key indicator of a cross-cutting line's modernity. Successful selection hinges on understanding product characteristics and production needs, integrating cutting technology, automation, and long-term strategy to invest in a stable, efficient, and scalable system—ultimately securing a competitive edge.

This detailed analysis aims to empower your decision-making. For specific applications or materials, further tailored discussions are available.