Application Fields and Ultimate Selection of Inspection Machine and Rewinding Machines

I. Core Functions and Technical Features of Inspection and Rewinding Machines

1.1 Core Functions

The primary functions of inspection and rewinding machines include:

• Defect detection: Optical sensors (such as CCD cameras or infrared scanners) identify surface flaws like bubbles, black spots, scratches, and foreign objects.

• Automatic slitting: Precisely removes defective sections based on detection results to ensure continuous finished rolls.

• Tension control: Utilizes closed-loop servo systems or magnetic powder brakes to maintain stable tension during high-speed operation, preventing stretching or deformation.

• Rewinding and finishing: Re-rolls slit materials to meet customer specifications for dimensions and tension standards.

1.2 Technical Features

• High-precision detection: High-resolution CCD cameras paired with AI algorithms enable micron-level defect recognition.

• Intelligent control: Integrated PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) allow one-touch parameter adjustments.

• Modular design: Customizable detection modules (e.g., transmissive or surface inspection) based on customer needs.

• Energy efficiency: Incorporates variable-frequency drive technology to reduce power consumption and enhance production efficiency.

II. Core Application Areas: Spanning High-Demand Roll Production Chains

The value of inspection and rewinding machines lies in upgrading the traditional "production-offline sampling" model to a closed-loop quality control process of "production-online full inspection-immediate processing." Key application areas include:

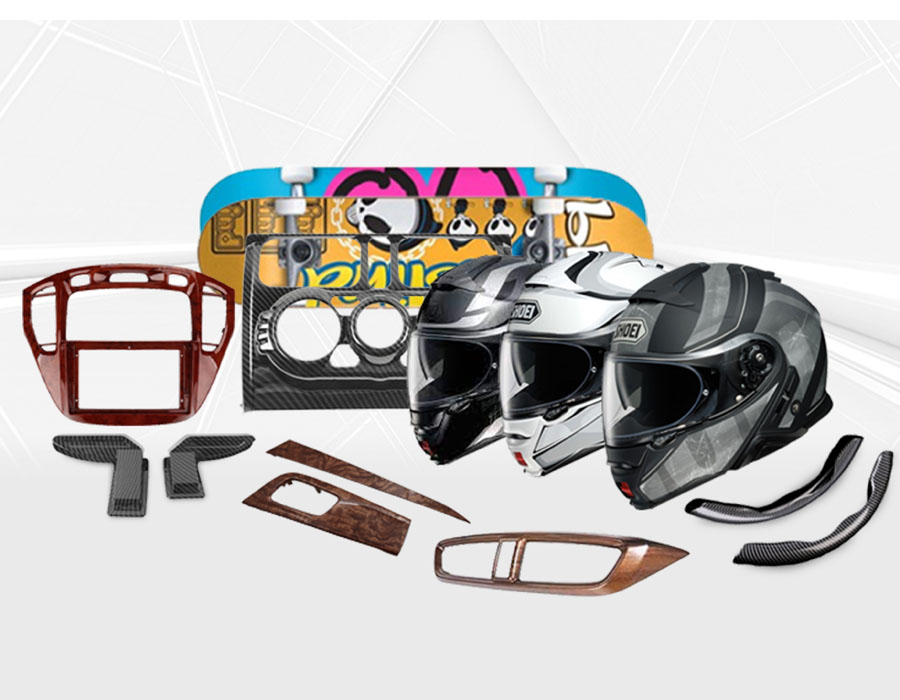

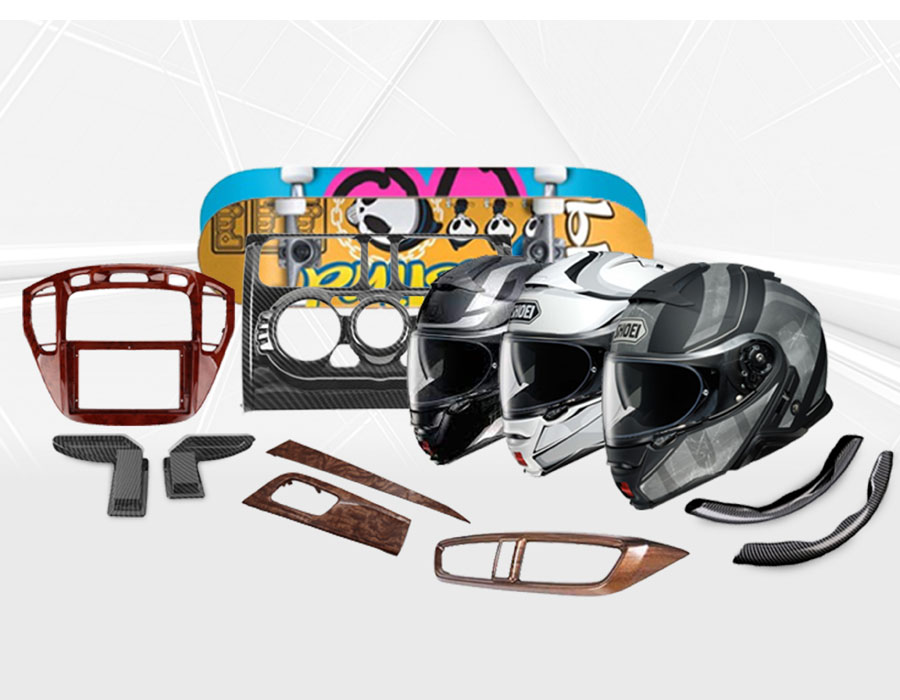

Film industry: The most widely used sector. Whether for packaging films like BOPP, CPP, and PE, or industrial films like lithium battery separators, optical films, and protective films, tolerance for defects such as pinholes, black spots, gels, scratches, streaks, and contamination is extremely low. Inspection and rewinding machines enable real-time detection and marking of flaws at high speeds (exceeding 1000 meters/minute), ensuring every delivered roll meets stringent standards.

Paper and nonwoven industry: For specialty paper, decorative paper, high-end printing paper, and medical hygiene nonwovens, detecting defects like dust, holes, pulp lumps, color variations, and uneven thickness is critical. Precise tension control during rewinding also prevents wrinkles and deformation.

Metal foil industry: Such as aluminum and copper foils used in capacitors and lithium battery current collectors. Inspection and rewinding machines detect defects like holes, oxidation, wrinkles, and thickness deviations, while advanced winding technology prevents foil creasing or damage.

Composite and flexible materials industry: Including label materials, tapes, insulating materials, and textile fabrics. The equipment not only detects material flaws but also performs secondary processes like slitting and laminating during rewinding, enabling multifunctional use.

III. Ultimate Selection: Scientific Decision-Making Based on Systematic Evaluation

Choosing the right inspection and rewinding machine is far more than a simple parameter comparison—it requires a multidimensional engineering approach integrating technical, economic, and production factors. Below is the key decision-making framework for the "ultimate selection":

Precise definition of core requirements:

• Material properties: Clarify width, thickness range, substrate tension sensitivity, and surface gloss (affecting light source selection).

• Defect types and precision: Essential defect categories (e.g., micro pinholes require high-resolution cameras, while transparent film scratches need specialized lighting) and detection accuracy (e.g., minimum detectable flaw size).

• Production speed and efficiency: Maximum line speed and required rewinding efficiency (roll change time, splicing methods, etc.).

• Data management needs: Whether full quality reports, defect pattern analysis, and production batch tracking are necessary.

In-depth technical configuration assessment:

• Inspection system: The core component. Focus on camera resolution (line scan or area scan), light source type (LED, fluorescent, infrared), and layout (transmissive or reflective). Superior detection software algorithms determine false-positive and false-negative rates, requiring physical sample testing for validation.

• Mechanical and electrical performance: The machine’s rigidity, tension control system (fully automatic PID or advanced servo vector control) accuracy and stability directly impact winding quality and material loss. The drive system (AC servo drive) grade affects speed and responsiveness

• Slitting and rewinding unit: Blade precision and durability, winding shaft rigidity, and automation levels for roll changes and taping.