Technical Characteristic Analysis

Digital printing presses employ plate-free printing technology, directly controlling imaging devices through electronic data to achieve precise transfer of ink or toner onto substrates.

Their core advantages include:

Zero plate-making cost, enabling true short-run economic efficiency

Support for variable data printing (serial numbers, QR codes, personalized content)

Quick job changeover, reducing production preparation time

Environmentally friendly, minimizing chemical usage and waste generation

Application Scenarios Focus

Food packaging bag labels: Meeting short-run demands for seasonal promotions, region-limited editions, etc.

Pharmaceutical labels: Serialized markings compliant with FDA traceability requirements

Industrial labels: Asset labels, logistics labels containing variable data

Personalized customization: Small-batch premium labels for wedding gifts, high-end consumer goods, etc.

Considerations for Integration with Bag-Making Processes

Special attention must be paid to the compatibility of digitally printed labels with subsequent bag-making processes, focusing on the abrasion resistance, fold resistance of inks/toners, and their suitability for lamination processes. UV-curable digital printing performs excellently in the flexible packaging field, with prints possessing good mechanical resistance and chemical resistance.

-

II. Intermittent Flexographic Printing Press: Precision Solution for Short to Medium-Run Labels :

Equipment Structure and Working Principle

Intermittent flexographic printing presses use a reciprocating paper feed mechanism. The substrate moves intermittently during the printing process, with printing occurring during the stationary moments.

This design makes them particularly suitable for:

Adaptability to various materials (paper, film, self-adhesive)

Integration of post-processing steps (die-cutting, hot stamping, laminating)Cost-effectiveness balance for short to medium-run jobs

Technical Advantages and Limitations

Advantages:

High registration accuracy, especially suitable for fine patterns and small text Capable of integrating various finishing units for one-stop production Relatively lower equipment investment, suitable for small and medium-sized label printing enterprises

Limitations:

Relatively slower printing speed (typically 30-50 meters/minute)

Higher production cost for long-run jobs

Slightly higher material waste rate compared to continuous printing equipment

Key Application Points Related to Bag-Making

For label products requiring subsequent bag-making, intermittent flexo presses can perform die-cutting, waste stripping, and other processes inline, producing finished labels ready for automatic or manual application. When printing film-based labels, special attention must be paid to the stability of the tension control system to ensure the flatness of the printed material meets the requirements for high-speed bag-making.

-

III. Sleeve-Type Flexographic Printing Press: Advanced Choice for Efficient Medium to Long-Run Production :

Technological Innovation and Efficiency Breakthrough

Technological Innovation and Efficiency Breakthrough

Sleeve-type flexographic printing presses use lightweight sleeve technology to replace traditional plate cylinders, bringing revolutionary improvements:

Quick plate change: Sleeve replacement time can be reduced to 15-30 minutes, cutting downtime by over 40%

Seamless plate material: Eliminates the plate seam issue of traditional flexo, enabling continuous pattern printing

High line screen printing: Supports high-precision anilox rollers of 150-200 lines per inch

Application Advantages in the Flexible Packaging Label Field

Large-volume food packaging labels (e.g., snack bags, frozen food bag labels)

Continuous production of roll-fed labels for daily chemical products

Large-scale production scenarios paired with high-speed automatic bag-making machines

Labels requiring special effects like spot colors, metallic colors, etc.

Performance Evaluation

Printing Quality: Sleeve technology reduces mechanical vibration, improving dot reproduction and registration accuracy.

Production Efficiency: Plate change time is significantly shortened, increasing overall equipment utilization by 25-40%.

Cost-Effectiveness: Clear unit cost advantage for medium to long-run jobs (5,000-50,000 meters).

Special Value in the Flexible Packaging Label Field

Sleeve-type flexo presses are particularly suitable for flexible packaging label printing needs. Their good adaptability to film materials (PE, PP, PET, etc.) and excellent highlight printing capability can meet the dual standards of visual appeal and durability required by industries like food and daily chemicals. When coordinated with bag-making processes, their stable tension control and precise registration capability ensure positional consistency of labels during subsequent lamination and bag-making processes.

-

IV. Stack-Type Flexographic Printing Press: Paradigm of Multifunctional Integration and Flexible Configuration :

Modular Design Philosophy

Stack-type flexographic printing presses employ independently arranged horizontal printing units in a straight line. Each unit is equipped with an independent impression cylinder and inking system, providing unparalleled flexibility:

Scalability: Printing color stations can be expanded from 4 to 12 or even more.

Process Combination: Capable of integrating various processes like flexo, gravure, screen printing, hot stamping, die-cutting.

Inline Processing:< Completing the entire process of printing, varnishing, laminating, and die-cutting in a single pass.

High-End Label Production Applications

Cosmetic Labels:Special effect treatments like multi-color gradients, metallic inks, local varnish.

Beverage Labels:Requirements for fine lines, small fonts, high-precision registration.

Anti-Counterfeit Labels: Application of precise registration, microtext, special inks.

Film-Based Self-Adhesive Labels:For flexible packaging like stand-up pouches, zipper bags.

Integration Strategy with Automated Bag-Making Lines

Stack-type flexo presses are typically equipped with advanced pre-registration and automatic registration systems. The printed web can be directly connected to automated bag-making production lines.

-

V. Central Impression Cylinder (C.I.) Flexographic Printing Press: Classic Solution for Economical Large-Volume Production :

Structural Features and Cost Advantages

C.I. flexographic printing presses use a vertically stacked printing unit structure, representing the most traditional and economical flexo solution:

Compact Layout: Small footprint, suitable for workshops with limited space.

Low Investment Threshold: Price for equivalent color stations is typically 30%-40% lower than stack-type.

Simple Operation: Relatively simple mechanical structure, lower maintenance skill requirements.

Applicable Scenarios and Limitations

Large-volume production of single-variety, standard labels.

Basic labels without extremely high registration accuracy requirements.

Preferred equipment for entry-level label printing enterprises.

Low-cost packaging solutions paired with simple bag-making machines.

Technology Upgrade Directions

Adding automatic registration systems to improve accuracy.

Retrofitting drying systems to accommodate UV inks.

Installing tension control systems to improve print quality on film materials.

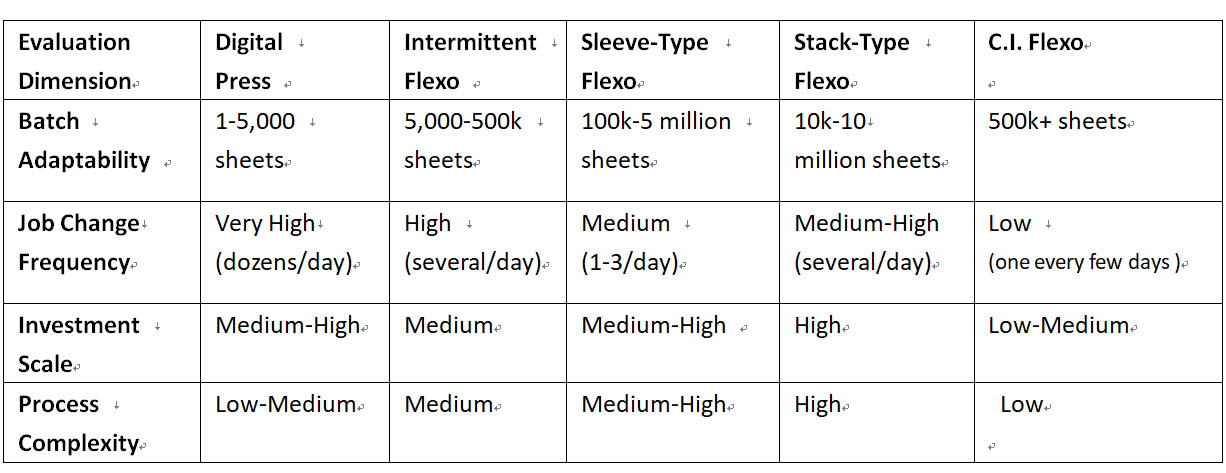

Ultimate Selection Matrix: Decision Framework for the Five Technical Paths

Four-Dimensional Evaluation Model Based on Production Needs

Material-Type-Oriented Selection Logic

Film Materials (PE, PP, PET):

Priority consideration for sleeve-type or stack-type flexographic presses.

Requires corona treatment units and precise tension control systems.

Compatibility with films produced by co-extrusion blown film machines needs key testing.

Paper Materials:

Intermittent flexographic presses offer the highest cost-effectiveness.

Requires attention to ink absorbency and surface flatness compatibility.

Specialty Materials (Metal Foil, Synthetic Paper):

Stack-type flexographic presses have the strongest multi-process integration capability.

Requires special impression design and drying system configuration.

Business Type Analysis

Short-Run/Personalization: Digital Printing Press

Medium-Run/Multi-Process: Intermittent Flexographic Press